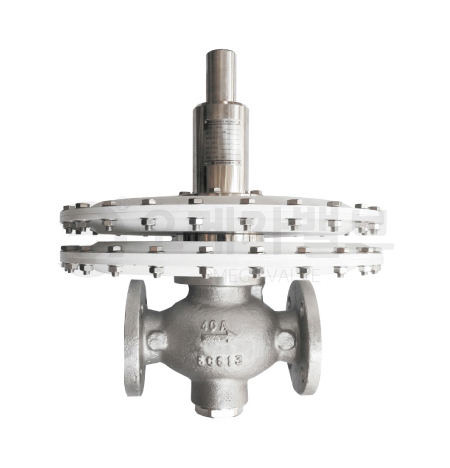

주요사양

| 모델 및 형식 | MPR-DD10 | MPR-SD10 | |

|---|---|---|---|

| 적용유체 | 기체(Air, N2 Gas, LPG 등) | ||

| 적용온도 | 5 ~ 80℃ | ||

| 1차측 적용압력 | Max. 0.1Mpa(1.0bar) | Max. 0.5Mpa(5.0bar) | |

| 2차측 설정압력 범위 | 0.0005~0.001Mpa(0.005~0.01bar) | 0.001~0.003Mpa(0.01~0.03bar) 0.003~0.005Mpa(0.03~0.05bar) 0.005~0.020Mpa(0.05~0.20bar) |

|

| 최대 감압비 | 100:1(Extra 200:1) | ||

| 밸브 전후의 최소 차압 | 0.01Mpa | ||

| 재질 | 본체 | A216 WCB, A105, Stainless Steel 304 | |

| 시트, 디스크 | Stainless steel 304 또는 316 | ||

| Diaphragm | EPDM | ||

| 접속방식 | Screw type | KS PT Screw, NPT, BS PT | |

| Flange type | KS 10K / ANSI 150lb | ||

| 본체 내압시험 | 공칭 적용압력의 1.5배(수압) | ||

| 기타 옵션 사항 | - Optional Pressure Gauge (Out or In & Out). / - 사용환경에 따라 Special Painting 실시. |

||

외관치수

| SIZE | L | H1 | H2 | ØA | |

|---|---|---|---|---|---|

| MPR-SD10 | MPR-DD10 | ||||

| DN15 | 184 | 64 | 252 | 298 | 284 |

| DN20 | 184 | 64 | 252 | 298 | 284 |

| DN25 | 184 | 82 | 264 | 312 | 284 |

| DN32 | 184 | 82 | 264 | 312 | 386 |

| DN40 | 222 | 97 | 308 | 356 | 386 |

| DN50 | 254 | 105 | 319 | 367 | 386 |

감압밸브 관련 용어

| 1차측 압력(Primary pressure) | 감압밸브 본체내의 입구측 압력 또는 감압밸브에 가까운 배관내의 압력 |

| 2차측 압력(Secondary pressure) | 감압밸브 본체내의 입구측 압력 또는 감압밸브에 가까운 배관내의 압력 |

| 설정압력(Set pressure) | 최소조절 가능 유량에 있어서의 2차측 압력 |

| 오프셋(Off-set pressure) | 2차측의 압력을 설정 후 최초 조절 가능 유량부터 정격유량까지 점차적으로 증가 시켰을 경우 떨어지는 압력, 즉 설정압력과의 차이 입력 |

| 체절 승압(Lock up pressure) | 감압밸브의 2차측 흐름을 차단하였을 때 순간적으로 상승하는 압력 |

| 최소 조절 가능 유량(Minimum adjustable flow) | 밸브를 서서히 개방 후 안정된 흐름을 보전할 수 있을 때의 유량 |

| 정격유량(Rated flow) | 1차측의 압력을 일정하게 하고 소정의 off-set 내에서의 최대유량 |

유량 특성 곡선

|

압력 특성 선도

|